What to expect when working with Jones Metal

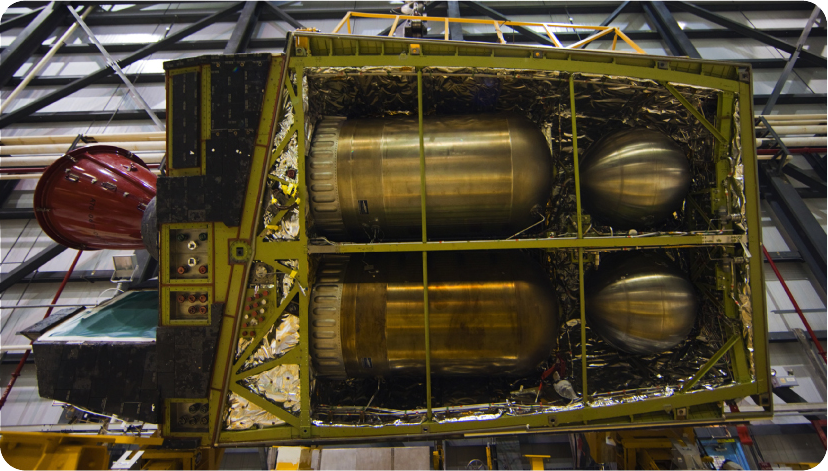

Businesses should consider Jones Metal for their space projects because of our unique combination of technical expertise, quality focused approach, and collaborative spirit. We don’t just manufacture parts; we partner with our clients to optimize designs for manufacturability, ensuring the efficient production of high-quality components critical for space applications. Our ability to work with challenging materials and meet tight tolerances makes us an ideal choice for the space industry’s demanding requirements.

Our Process

At Jones Metal Development, we understand that each project in the space industry is unique. To ensure we meet your specific needs, we’ve developed a streamlined 3-step process for our clients:

Provide Project Requirements

We begin by gathering all necessary information from you, including prints, CAD models, and required volumes. This comprehensive overview allows us to fully understand your project’s scope and specifications.

Meet with Experts

Our team of industry specialists will meet with you to address any questions or clarifications. This step is crucial, especially for quality-related aspects such as inspection methods and quality plans. For larger projects, we develop detailed plans before providing a quote.

Review Custom Plan

Once we have a clear understanding of your project and have addressed all technical aspects, we provide you with a detailed timeline and pricing information. This allows you to make an informed decision and ensures transparency throughout the process.

Our Capabilities

- Used for lower temperature processes

- Primary applications: aging, annealing, and stress relieving

- Flexibility to adapt processes for specific customer needs

- Used for lower temperature processes

- Primary applications: aging, annealing, and stress relieving

- Flexibility to adapt processes for specific customer needs

- Used for lower temperature processes

- Primary applications: aging, annealing, and stress relieving

- Flexibility to adapt processes for specific customer needs

- Used for lower temperature processes

- Primary applications: aging, annealing, and stress relieving

- Flexibility to adapt processes for specific customer needs

- High-temperature units for solution treating

- Rapid quenching capabilities

- Ability to freeze parts to maintain softened state for forming

- High-temperature units for solution treating

- Rapid quenching capabilities

- Ability to freeze parts to maintain softened state for forming

- High-temperature units for solution treating

- Rapid quenching capabilities

- Ability to freeze parts to maintain softened state for forming

- High-temperature units for solution treating

- Rapid quenching capabilities

- Ability to freeze parts to maintain softened state for forming

Trust Jones Metal With All Your Space Metal Parts Manufacturing Needs

No matter the size or complexity of your order, Jones Metal can complete in-house hydroforming, heat treating, stretch forming, and other services to craft the precision aerospace parts you need. Whether your company needs one component or 200, our professionals can help. Contact us today to discuss your aviation and aerospace component manufacturing needs!